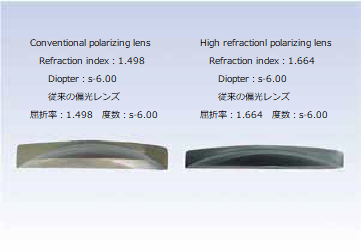

Comparison of polarizing lenses

偏光レンズの比較

Refraction index of conventional polarizing lenses was as low as 1.50. In addition, the lens edge used to be thick and the whole weight was heavy. Making full use of our self-developed technology, we succeeded in eliminating these defects by developing polarizing lenses with thin edge and supply them to major lens manufacturers both at home and abroad. They are manufactured first by casting liquid resin with high refraction index into the mold form for lenses. Then, polarizing film which is 40 micrometers thick is inserted into the liquid resin so that it is evenly kept in a given position from the lens surface and, thereby, polarizing lens with over 1.60 refraction index is molded.

従来、偏光レンズは屈折率が1.50と低いものしかなく、レンズの縁厚が厚くなり、重くなる欠点がありました。当社は、独自技術により縁厚の薄い偏光レンズの開発に成功し、国内外の大手レンズメーカーに提供しています。レンズを作る型の中に屈折率の高い液体樹脂を入れ、その液体中に厚さ40マイクロメートルの偏光フィルムをレンズの表面から一定の位置に均一に挿入して、屈折率1.60以上の偏光レンズを成形しています。

Manufacturing of medical plastic lenses

医療用プラスチックレンズの製造